Weaving Machinery

Toyota Industries develops and manufactures weaving machines with two different weft insertion systems, such as air and water systems. We provide our customer with the most state-of-the-art weaving machinery and weft insertion system for a broad variety of applications. We provide excellent speed and reliable performance.

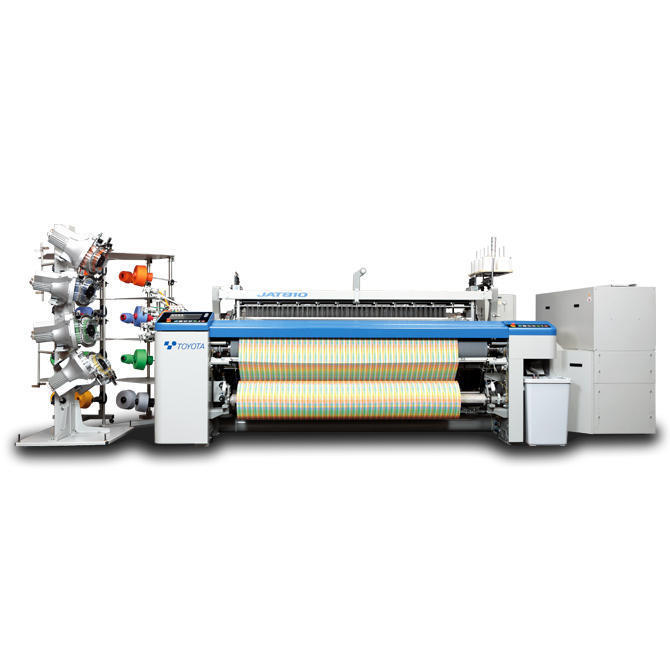

JAT810 (Air Jet Loom)

Based on the most advanced technology and design concepts, the JAT Series enables our customers with the widest range of applications at the lowest possible production cost. The JAT810 boasts a wide range of original Toyota features, including an air-saving system, flexible insertion system (FIS) and multi–tandem nozzles to reduce energy consumption. Our state-of-the-art electronic shedding system (e-shed) enables our customers to reach new horizons in developing the most spectacular styles at speeds far beyond any other shedding system’s running speed. In addition, a newly developed function panel and a factory management system dramatically improve the operability and control of the entire weaving process.

Our famous JAT710 has been a best seller since its debut in 2003. JAT710 sales have reached 70,000 units. This model continues to enjoy the number one market share worldwide for air jet looms (from 2003 to 2013). This weaving machinery has had many great customers around the world.

Now, we work with the new JAT810. The new JAT810 has inherited the JAT710’s legacy of superb performance while pursuing even greater energy savings and versatility combined with ease of use.

The JAT810 has evolved with the times and is designed to meet all your weaving needs. It has the following features:

- The newly developed air-saving system reduces machine operation costs. This air-saving system achieves low-pressure weft insertion. It also enables a reduction in supplied pressure from the air compressor.

- A further evolved electronic shedding motion: Independent servomotors drive individually held frames. It is the ultimate shedding device with operability and versatility surpassing that of dobby units as well as high-speed capabilities equal to or greater than cam shedding. The basic system has been newly redesigned for the third generation of this device; high-performance motors and servo controllers were newly developed in-house for this shedding motion. Fabrics that were previously highly challenging to weave can now be woven at high speed.

- New weave assist system (WAV): In addition to existing functions (ICS settings, electrical parameters, and mechanical parameters) that enable the optimum weaving conditions to be set automatically simply by selecting the fabric parameters, a newly designed adjustment support function assists the operator with many tasks. For example, it assists in making adjustments to reduce stop marks and the number of faults. In addition, for quality control, WAS monitors the number of faults and abnormalities—such as excessive air consumption—triggers a warning, and shuts down the machine to prevent damage to the product. This maintains a high level of textile quality.

- Lower-vibration technologies enable stable high-speed operation.

Main specifications

Weft insertion

single electric drum, 2-, 4-, 6-, 8-color exchange electric drum

Nominal reed space

140cm, 150cm, 170cm, 190cm, 210cm, 230cm, 250cm, 260cm, 280cm, 300cm, 340cm, 360cm, 390cm

Shedding

negative cam, positive cam, crank, dobby, electric shedding, jacquard

LWT810 (Water Jet Loom)

Innovation for the Future—Reliability from the Past: Meet Our LWT 810 Water Jet Loom

The LWT810 enhances productivity and quality with the latest technological advancements that customers expect from Toyota while achieving the highest energy savings to protect our environment.

The new Toyota LWT810 Water Jet Loom is your investment in the future. It includes the following features:

- High quality and improved productivity: It offers a short stroke and extending weft insertion time, causing drastic improvements to high-speed operation and enhanced quality while placing minimum strain on the yarn.

- Operability and support: The new function panel of the LWT810 offers the latest in electronic technology advancements and troubleshooting, including enhanced visibility, improved machine operation functionality, and upgraded handling.

- Factory Management: The new factory management system—based on the Toyota Monitoring System—offers an increased management level of productivity and quality in real-tie by displaying shift reports, actual factory floor layout, and operation status in various formats.

Main specifications

Weft insertion

single pump, double pump

Nominal reed space

170cm, 190cm, 210cm, 230cm, 280cm

Shedding

negative cam, positive cam, crank, dobby

What can we do for you?

Please feel free to contact us.